Understanding the Basics of Injection Robots

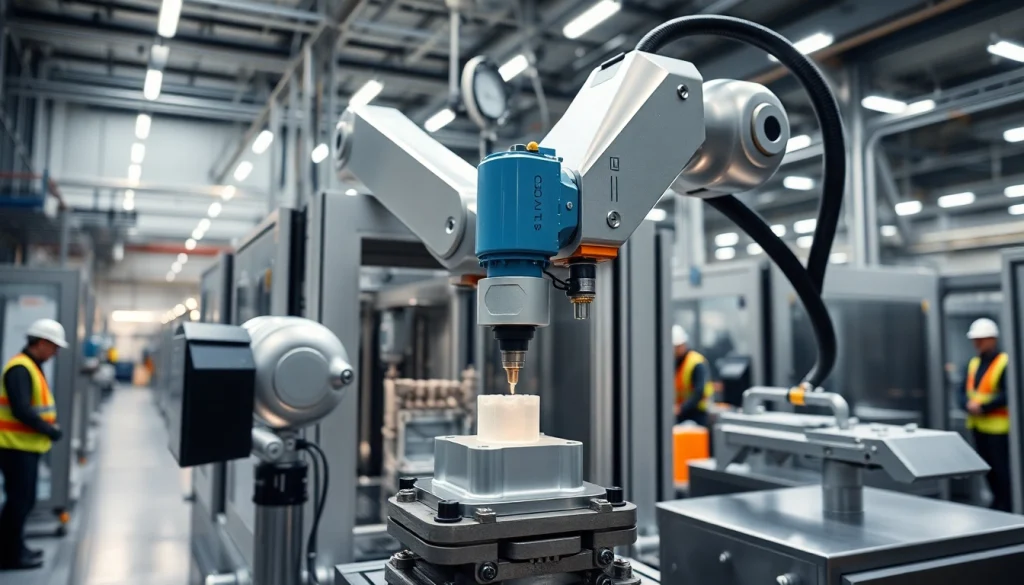

In today’s fast-paced manufacturing environment, Injection Robots play a critical role in enhancing productivity and efficiency. These sophisticated machines are designed to automate the injection molding process, allowing manufacturers to produce intricate plastic components with high precision. This article delves into the fundamentals of injection robots, exploring their components, functionality, and various types currently in use across diverse industries.

What is an Injection Robot?

An injection robot, often known as a robotic arm, is a specialized machine that automates the injection molding process. It utilizes advanced technology, including servomotors and programmable logic controllers (PLCs), to accurately position and control the injection of molten plastic into molds. By replacing manual labor, injection robots not only speed up production but also significantly enhance the consistency and quality of the final products.

Key Components and Functionality

The effectiveness of an injection robot stems from its intricate components and functionality. Key components include:

- Servo Motors: These are the heart of the robot, providing precise movement and control.

- End Effectors: Devices attached to the robot arm that manipulate the injection process, such as sprue pickers and grippers.

- Controllers: Computers that manage the robot’s operations, ensuring accurate timing and sequence of movements.

- Feedback Sensors: Tools that provide real-time data on the robot’s position and operational status.

The integration of these components allows injection robots to perform tasks such as loading materials into the injection machine, removing finished parts, and assisting in secondary operations like packaging or assembly.

Types of Injection Robots in Use

Injection robots come in various configurations, each tailored to specific production needs. The most common types include:

- Cartesian Robots: These robots operate on linear paths and are ideal for straightforward pick-and-place tasks.

- Articulated Robots: Featuring rotating joints, these robots provide greater flexibility and can handle complex tasks in confined spaces.

- Delta Robots: Known for their speed and efficiency, delta robots are perfect for high-speed pick-and-place operations.

- SCARA Robots: These robots offer a combination of vertical and horizontal movement, making them suitable for assembly tasks.

Benefits of Implementing Injection Robots

The adoption of injection robots offers numerous advantages to manufacturers, significantly improving their operational efficiency and product quality.

Increased Precision and Consistency

One of the primary benefits of using injection robots is the remarkable precision they provide. Unlike human operators, these machines can execute tasks with a high degree of accuracy, ensuring that every part meets the specified tolerances. This consistency translates into fewer defects, reduced waste, and improved overall product quality.

Cost-Effectiveness and Efficiency Gains

Investment in injection robots may seem significant at first, yet the long-term cost savings are substantial. Automated systems reduce labor costs and operational time, which leads to a lower cost per part produced. Moreover, robots can operate continuously, minimizing downtime associated with manual processes.

Reducing Labor and Safety Risks

Manufacturing environments can pose various hazards to human workers, such as repetitive strain injuries and exposure to harmful materials. By implementing injection robots, companies can minimize the risk associated with hazardous tasks, ensuring a safer workplace while freeing human operators to focus on more complex and strategic activities.

Challenges and Considerations in Adoption

Despite their numerous benefits, integrating injection robots into an existing manufacturing setup is not without challenges. Here’s a closer look at some of the considerations businesses should keep in mind.

Upfront Costs and Investment Justification

The initial investment required for acquiring and integrating injection robots can be daunting, especially for small to medium-sized businesses. Companies must conduct a thorough cost-benefit analysis to justify the investment. Calculating potential savings from improved efficiency and reduced labor costs is crucial for making an informed decision.

Technical Skill Requirements for Operation

While injection robots streamline operations, they also necessitate a skilled workforce to program and maintain these systems. Companies may need to invest in training programs or hire skilled technicians, which could add to the upfront costs associated with automation.

Integration with Existing Manufacturing Systems

Seamless integration of injection robots with existing manufacturing processes is essential for maximizing their potential. This might involve upgrading or modifying current machinery, which can be a complex and time-consuming endeavor.

Real-World Applications of Injection Robots

Injection robots have been successfully implemented across various industries, demonstrating their versatility and effectiveness. Let’s explore some real-world applications and case studies.

Case Studies of Successful Implementations

For example, a leading automotive parts manufacturer successfully integrated injection robots into their assembly line, resulting in a 30% increase in production speed and a significant reduction in scrap rates. Similarly, a consumer electronics company reported a 20% improvement in product quality after adopting robotic automation.

Industries Benefiting from Injection Automation

Several key industries are reaping the rewards of injection robot technology:

- Automotive: Used for producing parts like dashboards, bumpers, and engine components.

- Consumer Goods: Ideal for manufacturing items such as containers, covers, and other plastic components.

- Medical Devices: Ensures the precise creation of complex parts required for medical applications.

Emerging Trends and Innovative Uses

Recent advancements in technology have expanded the capabilities of injection robots. For instance, the integration of artificial intelligence (AI) allows for adaptive learning, enabling robots to improve their efficiency over time by analyzing production data in real time.

Future of Injection Robot Technology in 2025 and Beyond

As technology continues to evolve, the future of injection robots holds exciting possibilities. Here are some anticipated developments that could shape the industry.

Predictive Maintenance and IoT Integration

With the advent of the Internet of Things (IoT), injection robots can be equipped with sensors that monitor their performance in real-time. This capability allows for predictive maintenance, where potential issues are identified before they result in downtime, thus ensuring continuous operation.

Environmental Considerations and Sustainability

As sustainability becomes a priority for many manufacturers, injection robots are expected to play a significant role in minimizing waste and energy consumption. Eco-friendly materials and processes will likely be integrated into future robotic systems, aligning with global efforts towards sustainable manufacturing practices.

The Role of AI in Enhanced Automation

Artificial intelligence will increasingly influence the operation of injection robots. AI can help optimize processes, reduce cycle times, and enhance decision-making capabilities, further improving efficiency and output quality.